- Lean manufacturing/ Lean Production System

- Just-In-Time System

This article will explain how lean manufacturing came into existence and how the just-in-time system was started. The Toyota Company was the one that established these concepts in the Operations and Supply Chain of the Car manufacturing industry. Almost all companies are now using these concepts to deliver the desired outputs efficiently.

One of the most outstanding companies in the world is Toyota. Additionally, Toyota is a firm that has practically every reason to fail, which is what makes it even more impressive. Japan had extremely few natural resources and a limited population because of its small size. Because of this, both labor and raw materials were quite expensive. Japan also frequently experiences natural disasters like earthquakes and tsunamis, which could destroy your factory in minutes. Thirdly, World War 2 broke out while Toyota was only two years old, and bombs fell from the sky.

Furthermore, even surviving was a significant concern at the time, let alone doing business. Additionally, Japan’s economy was in utter disrepair following the bombing of Hiroshima and Nagasaki and World War 2. Finally, despite all the odds against them, they were in a direct rivalry with American industry behemoths like General Motors and Ford Motor. Despite these challenges, Toyota has become one of the world’s most prosperous automakers.

In 2008, it even overtook Germany as the world’s top automaker. Toyota’s market capitalization surpassed that of Ford, General Motors, and Honda in 2016. This raises the question of how Toyota thrived in such challenging market conditions. What was their actual business plan? What, more importantly, can we take away from this excellent case study?

This tale takes place in 1950 Japan, 13 years after Toyota’s founding, when that country was in total disarray following World War 2. Toyota nearly made it through the war by alternating between producing trucks and vehicles for the military. Even after 13 years of work, the company’s condition was so dismal that Toyota Motors built just 11,000 cars in the entire year.

On the other hand, Ford Motor Company manufactured more than 1 million cars during the same period. And because of this stark difference in output, Toyota’s top manager EG Toyota and several of his engineers visited the Ford Rouge facility to observe how they improved their manufacturing procedures. However, following this trip, they concluded that replicating and enhancing the rouge system would not be effective in Japan. Why? Because Toyota’s financial situation was extremely precarious.

Additionally, Japan was still recuperating from the negative impacts of the World War, which left the nation cash- and foreign exchange-starved. Toyota could not purchase the most recent Western production required to increase production and enhance production efficiency. Therefore, Toyota could not compete with American firms in the two most essential production components: capital and machinery.

Any ordinary engineer would now quit at this point and claim that he could never compete with the Americans. However, EG Toyota founder Kiichiro Toyoda was not a typical engineer. Even though he knew the odds were stacked against him, he and his team continued to work tirelessly to figure out how to create a system that competes with American manufacturers. And it was at that point that they understood that, even though they could not compete with the Americans in terms of capital and apparatus, there was one critical area in which they could defeat them, and that area was efficiency. He, therefore, developed the concept of the LEAN PRODUCTION SYSTEM.

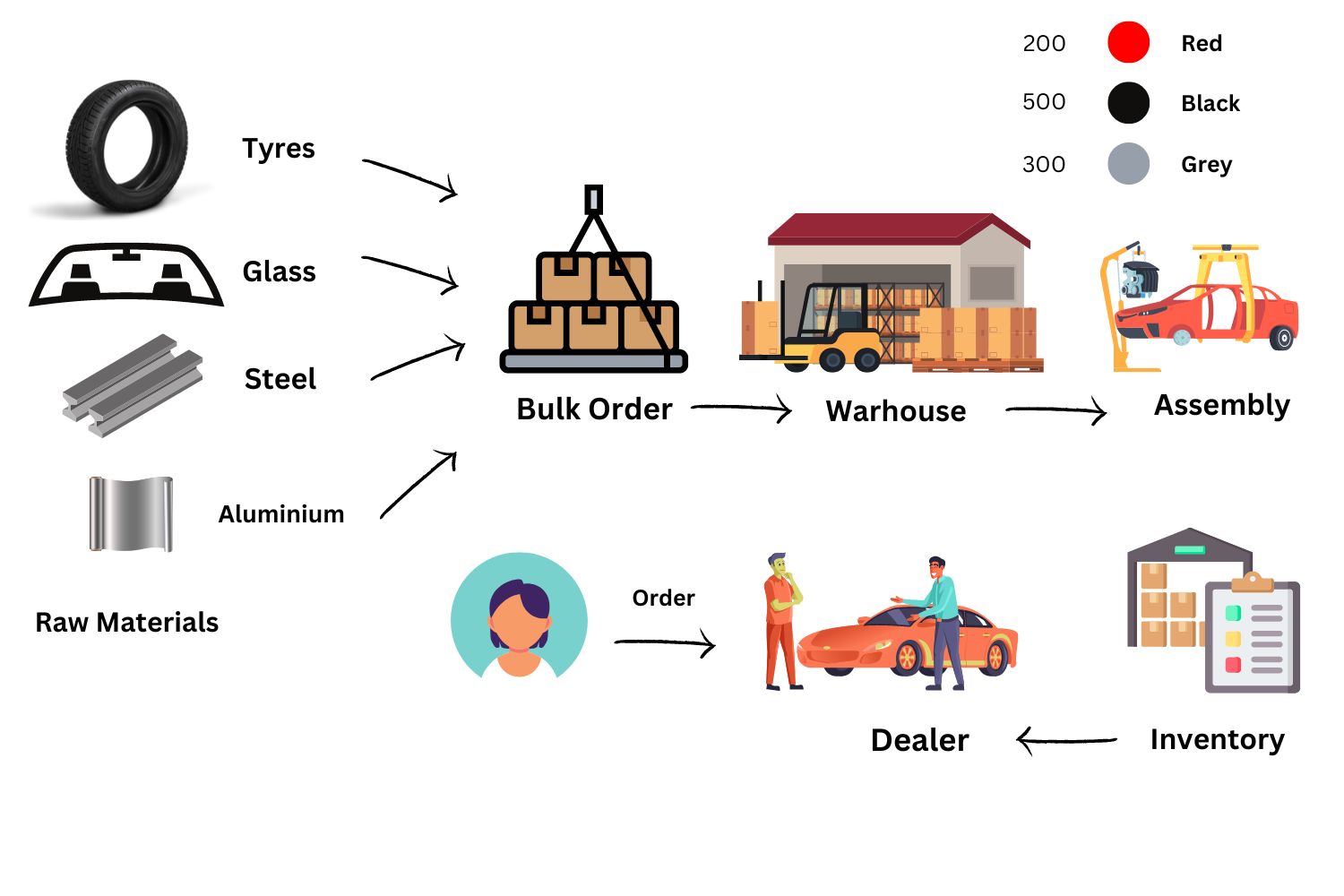

To save money on the cost of machine parts and raw materials, EG Toyota realized that US manufacturers’ typical mode of operation was to first predict demand to a certain extent before placing bulk orders. The corporation will construct 200 red vehicles, 500 black cars, and 300 grey cars if three different car colors must be sold: red, black, and grey. These cars will be ready for delivery and kept in inventory until the order is placed. And they are taken out and delivered to the consumer right away once the customer placed the order. However, the Toyota team discovered a significant issue throughout this process, which in turn caused a string of four significant inefficiencies. And it was the elimination of these inefficiencies that propelled Toyota to billion-dollar status.

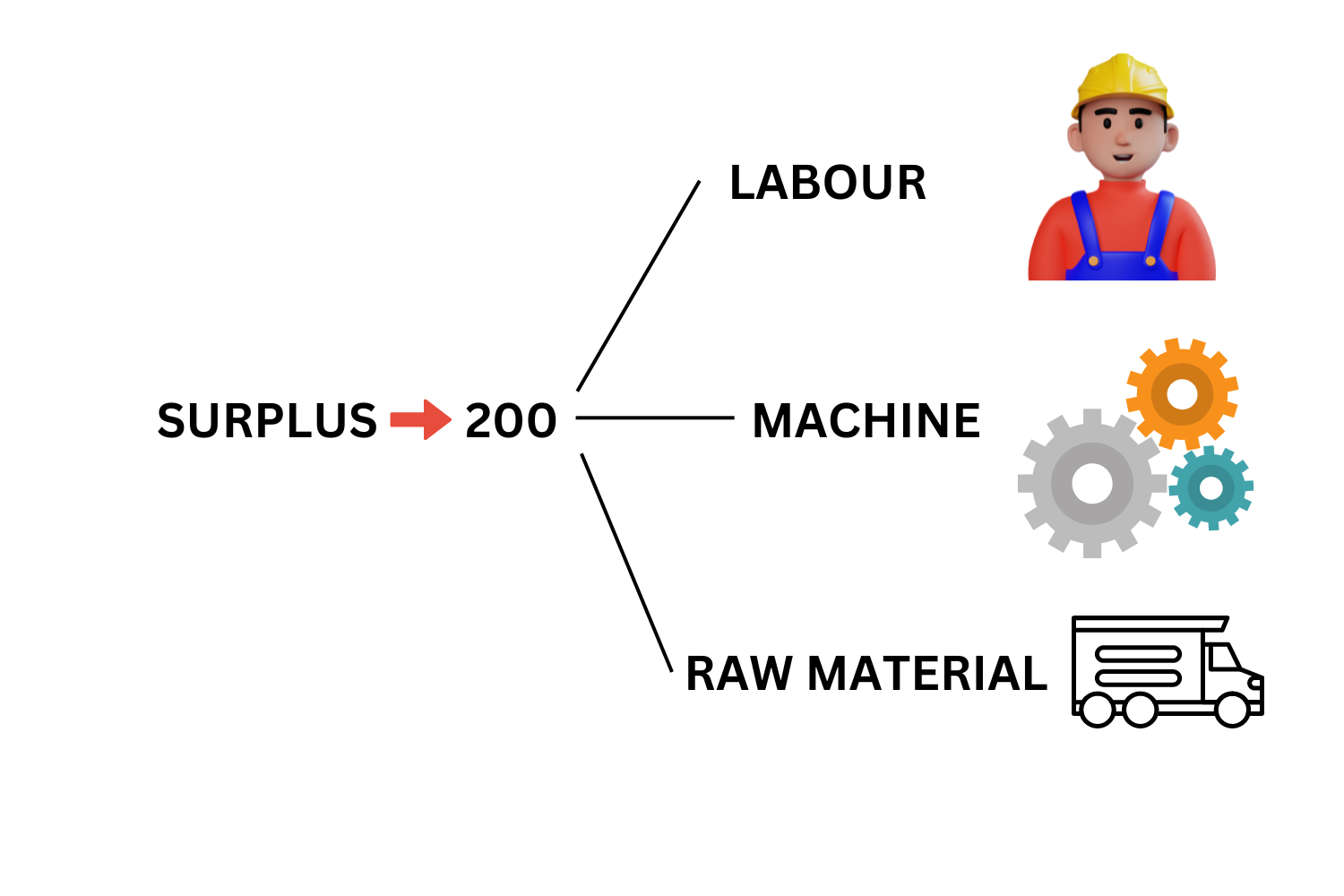

It altered how the automobile industry operated and the global supply chain. What were these inefficiencies, and how were they resolved? Did the Toyota team resolve team discover that manufacturing always used to create more automobiles than was needed and never ran a deficit when demand forecasting took place in the United States? As a result, it frequently results in an over-allocation of resources.

This resulted in the hiring of extra employees, the acquisition of more equipment, and the stockpiling of more supplies and goods. And as a result, the total cash costs increased without adding value. Second, extraneous personnel, machinery, and supplies inevitably result in overproduction. The third waste resulting from overproduction is an excessive stock of finished goods. In this instance, if there are 1000 different cars created, a significant quantity of land is being used, which raises maintenance, labour, and shipping expenses significantly.

This resulted in the hiring of extra employees, the acquisition of more equipment, and the stockpiling of more supplies and goods. And as a result, the total cash costs increased without adding value. Second, extraneous personnel, machinery, and supplies inevitably result in overproduction. The third waste resulting from overproduction is an excessive stock of finished goods. In this instance, if there are 1000 different cars created, a significant quantity of land is being used, which raises maintenance, labour, and shipping expenses significantly.

Finally, when all of these combined methods result in unnecessary capital investment, which is the fourth sort of waste, do you realize that, for instance, if a loan of $1 billion has been obtained and is used for overproduction, it will accrue an absurd amount of interest costs and result in extremely high prices with no return on investment? Additionally, this results in increased administrative expenses, depreciation charges, etc. Right now, it appears as though many things need to be adjusted at first. However, there was just one issue at hand when the Toyota team identified the source of this issue.

Demand forecasting resulted in over-inventory, which in turn caused a chain reaction that produced the four forms of waste. So, do you know what Toyota decided to do away with two of the supply chain’s most essential components: inventory and demand forecasting?

Toyota created a supply chain with no inventory and no demand forecasting. Let me introduce you to the world-class JUST-IN-TIME system. In addition to revolutionizing the automobile industry, this system also set the bar for supply chain management across all industries. This is how it transpired. The cars used to be available to consumers in pamphlets and showrooms rather than being made and kept in inventory. Toyota didn’t start building the car until the buyer placed the order. On the surface, this appears to be relatively easy. Here is how even a grossly simplified production process at Toyota might appear.

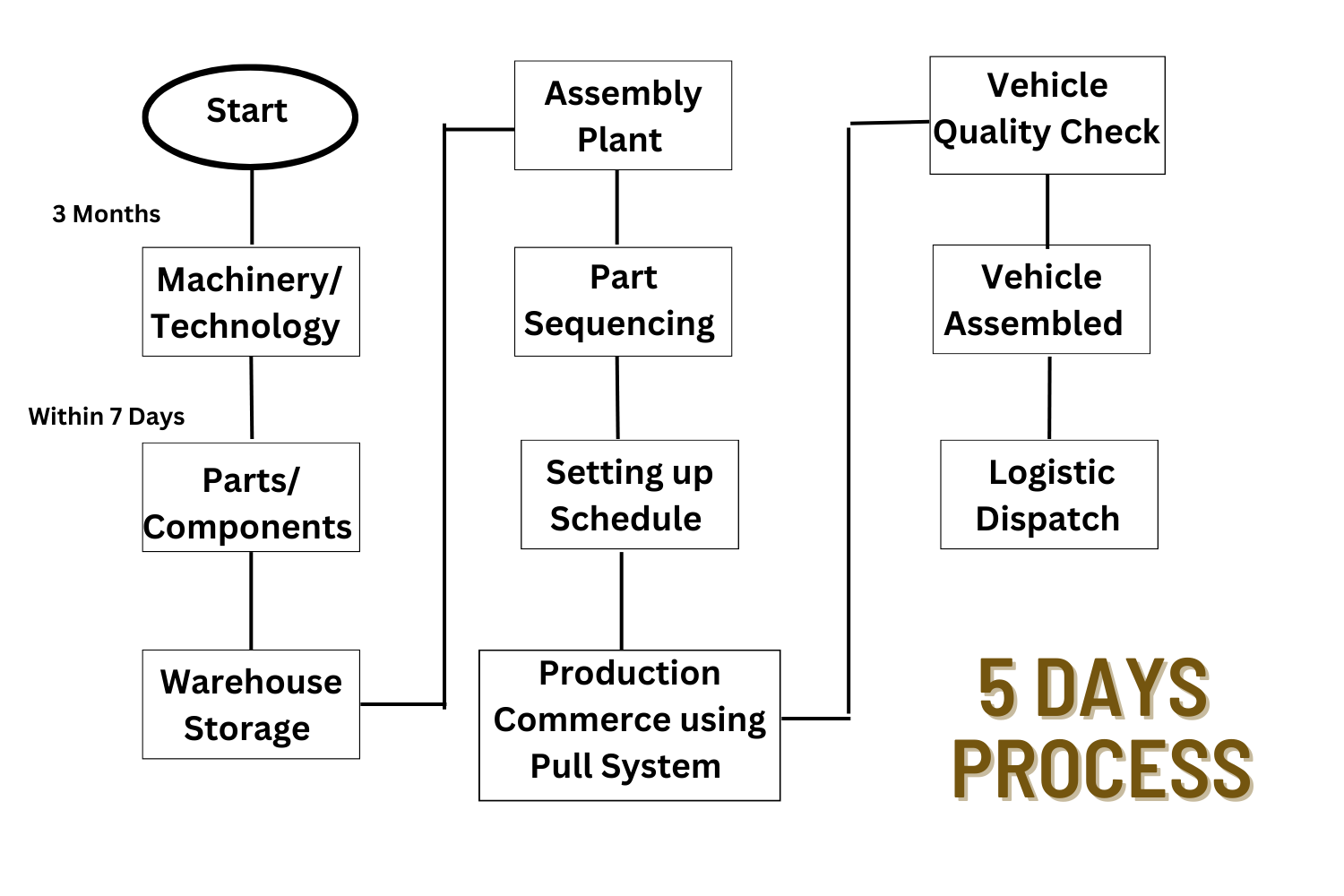

The machinery and technologies are purchased three months after the conceptualization and booking dates are set. The parts and components then arrive at the production centre in seven days. After orders flow in from various dealers across the nation, actual production begins, and the road moves toward assembly. Based on demand, the same amount of parts will arrive each day when this time comes. Therefore, only 9871 components will arrive the next day if 9871 components have been brought to the assembly. This occurred for one component and the hundreds employed in the assembly. Assembly activities then took place; the final step was the quality check. When built automobiles reach the dispatch zone, they are transported to the dealers by the orders they have been given as soon as possible. And according to the source cited in 2016, the full process is scheduled to take place in five days.

As a result, the company’s whole supply chain begins to operate based on actual demand rather than demand prediction. This is how Toyota’s just-in-time manufacturing process operates, when even a small delay may cost the corporation millions of dollars.

And for the remainder of the competition, Toyota now possessed three amazing superpowers thanks to this astounding precision.

- First, Toyota would sustain only minimal loss in the event of lower demand or even if an earthquake destroys the facility because they have almost no inventory and minimal component stock. Toyota even requested that its suppliers adhere to the just-in-time philosophy for their systems, which once again decreased the cost of the whole supply chain without putting the suppliers at a bottleneck.

- Second, all four types of waste were eliminated, leading to significant cost reductions. These cost reductions were so remarkable that when other businesses adopted JIT, their inventory levels dropped by 50%, and their lead times decreased by more than 80%. This led to significant cost reductions and a sharp rise in profit margins.

- Last but not least, Toyota’s production began to soar starting in 1955. They produced 22,786 vehicles in 1955, 46,417 in 1956, and 70,856 in 1957, and by 1965, they had nearly doubled that number, manufacturing 477,643 units.

This is how Toyota and its engineers created an iconic supply chain that allowed them to grow into the biggest and one of the most successful automakers in the world. They did this by finding the ideal balance between extreme efficiency and excessive risk.

Now, how can you, as an entrepreneur, use the just-in-time principle within your business? And what should we have learned from someone as legendary as EG Toyota? First, hardship always serves as a fertile foundation for innovation. So, to discover how to create the most effective systems, look back in time and locate instances where humans were forced to choose inefficiency. Because this is where the most amazing technological advancements that will enable you to outperform your rivals are happening. In this instance, Japanese adversity allowed Toyota to develop a just-in-time system that helped them defeat competitors like Ford and General Motors. The second lesson is never to copy and paste the same system to address an issue after researching the systems of your rivals or even your ideal companies. Always determine how your constraints differ from their constraints before selecting each step of execution with extreme caution. In this situation, I urge you to consider the risk associated with the strategy rather than merely being attracted by the just-in-time concept.