Menstruation Pad/ Sanitary Pad

The menstrual pad is a very useful product today. Many still find it difficult to use such a sanitary napkin today, and it is very important to use the right kind of sanitary napkin. Let us understand everything with the help of the following content.

What is meant by Menstruation or Menses?

The standard physical process of discharging blood and related material from the uterus through the vagina as part of the menstrual cycle is menstruation or menses.

Menstruation officially begins when a girl experiences her first menstrual cycle or menarche.

Why are sanitary napkins used?

In women, after every 28 to 30 days, they get bleeding from the vagina, which is called the period, scientifically called the “Menstrual Cycle.” This process takes place every month. Some women may experience this for 3 to 5 days, and for some, it may take 7 to 9 days. It starts at the age of 13 and till 45 or 50. This means every woman has to face these periods at least 500 times in their life span. And for this bleeding, sanitary pads are used, which hygienically collect that blood and dispose of it. In short Sanitary napkin or sanitary pad is an absorbent personal care product worn by a woman.

How the first sanitary napkins came into existence would surprise you all.

Believe it or not, World War I led to the invention of disposable sanitary napkins. American nurses in France discovered that their bandages for the troops could double as very absorbent menstrual pads. This led the bandage company to introduce disposable sanitary napkins in 1921. Disposable hygienic pads were first effectively marketed in the United States in 1921 after being developed in 1896.

Sanitary napkins are the most helpful product in today’s life. And the demand for napkins is more from the Indian public. In the early days, women used layers of cloth to absorb the blood, which was not absorbed correctly and could lead to stains. This was not hygienically safe and led to many diseases too. Today, sanitary napkins are the most demanding thing in the world, yet Indian women constitute only 20% to 30% who use or are affording to use.

Sanitary napkin is the most demanding and has a growing business. The use of hygienic sanitary pads and spreading its awareness is essential to today’s youth in both rural and urban, as many women, even today, don’t know the uses and benefits of this product and fall prey to allergies and diseases. Spending very little money can save us from many problems and get the target of any severe health risks.

Sanitary napkins are available in large numbers and wide varieties in the market, yet users are not educated enough about this. Today, Menstrual hygiene has been promoted by some governments and non-governmental organizations through health awareness campaigns and the free or discounted distribution of sanitary pads. Their quality, however, varies substantially.

Production of sanitary napkins is not much in India, and most of the napkins are imported from different countries.

Materials used in Sanitary Pads.

Various materials are used to make menstrual pads, and these materials vary by brand, style, and nation of origin.

The primary components of disposable menstrual pads are often bleached rayon (cellulose generated from wood pulp), cotton, and polymers. However, manufacturers are typically unwilling to disclose the precise composition of their products. Antibacterial and aroma ingredients are other options. Backsheet and polymer powder, a more powerful absorbent (superabsorbent polymers), are made of plastic. When moistened, the polymer powder transforms into a gel.

Raw materials used in Sanitary Napkins:

- Cellulose pulp (wood, cotton, polymers)

- Super Absorbent Polymer (SAP)

- Polyethylene back sheet

- Silicon paper

- Non woven fabric

- Gumming liner or hot melt seal

Three layers are usually used to manufacture menstrual pads.

- A top sheet is often made of perforated, non-woven polypropylene/polyethylene fibers. The top sheet collects menstrual fluid and is covered in an emollient for gentle touch with the vulva.

- The middle sheet is an absorbent polymeric core that stores menstrual fluid.

- A backsheet that stops menstrual fluid leaks from the pad.

Most sanitary pads use the same basic construction: a cellulose-based absorbent core sandwiched between a top sheet with a fluid-permeable surface and a backing with a moisture-impermeable surface (backsheet).

The function of Sanitary Napkins:

The primary purpose is to retain and absorb menstrual flow.

- It keeps clothes and underwear from becoming dirty

- Are both odor- and leak-resistant

- Skin-friendly and offering a high standard of cleanliness C

- comfortable to wear and does not have an ugly appearance

- They are provided in a variety of quality and sizes.

The process of making of menstruation pad

Given below are the seven stages of pad making process. This is the primary pad manufacturing process, and organic materials make a simple pad. Let’s get deeper to understand the process.

- Pulveriser machine: De-fibration of Pulp

- Pressing Machine: Core Coating Process

- Sealing and Embossing machine: pad sealed and embossed

- Trimming: To cut the pad in a pad shape

- Gumming Liner/ Silicon release paper application

- UV sterilization: sterilizing the manufactured pad

- Packaging

Stage 1: Pulveriser Machine

In this stage, the pine wood or cotton pulp is crushed and fibrated. De-fibration is the process of separating the pulp sheet into fibrous constituents. This crushed fibrous substance is called cellulose.

Stage 2: Pressing machine

This cellulose is filled in pad shape carved hollow tray, and blocks of the same shape are placed on that filling as seen in the 2nd image below. This plate of trays is then placed under the pressing machine, where they get compressed, and a pulp cake is formed.

Stage 3: Sealing and Embossing

Raw materials are placed layer by layer, creating a sandwich in which the pulp cake is embossed and sealed. The image below shows that the first raw material identified is PE (Polyethylene) back sheet at the bottom. This sheet is breathable. 2nd layer is the pulp cake obtained in the previous stage, and then the non-woven fabric is placed on top. This fabric is also called artificial cloth. This 3-layer structure is then placed inside the machine where it gets sealed and embossed.

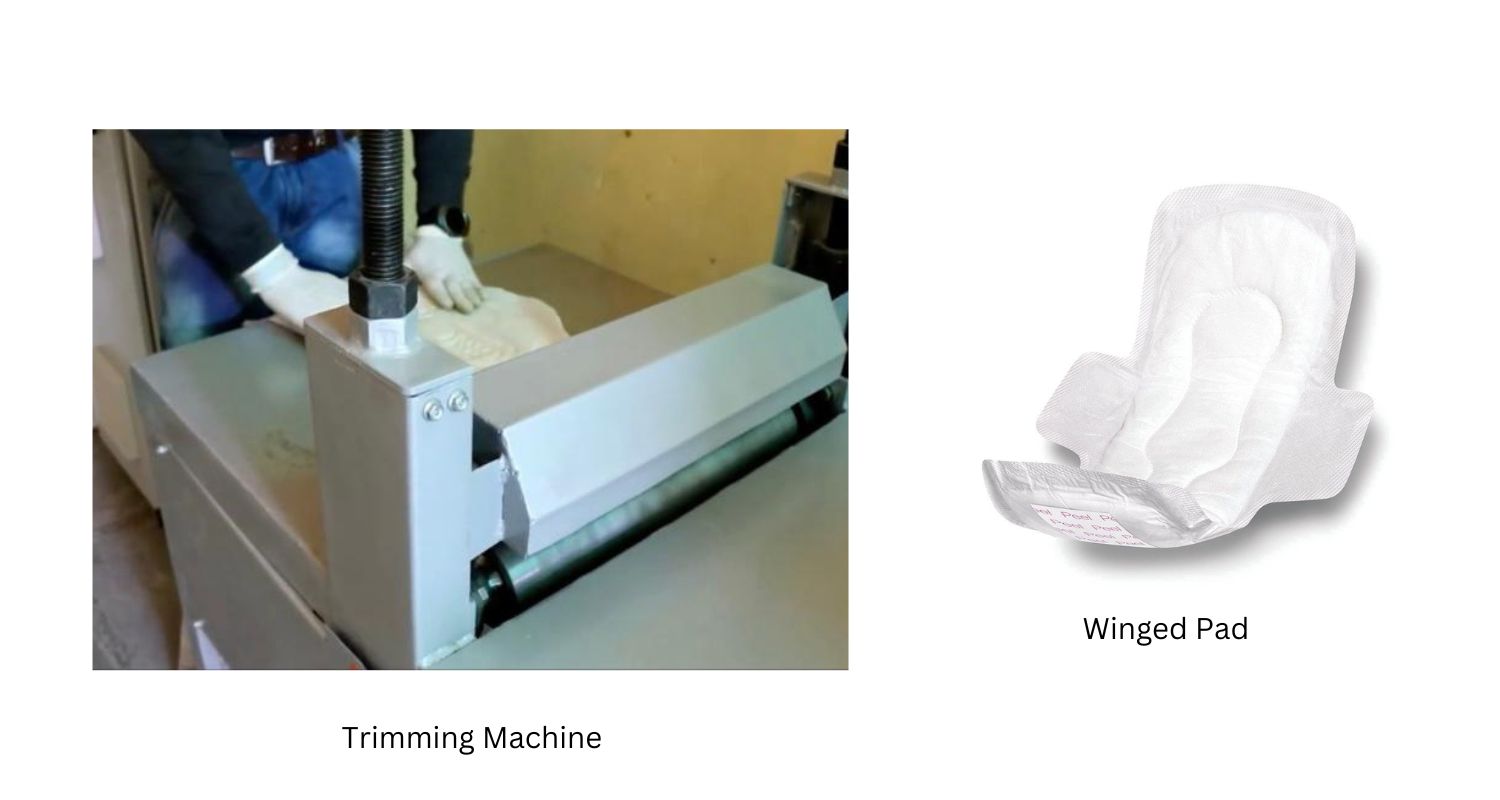

Stage 4: Trimming

The sealed and embossed pad is trimmed and shaped into a winged pad. A trimming machine is also called a pad-cutting machine. The steel or aluminium plate-like structure is placed on the pad which then goes through the machine. This machine presses and cuts the pad perfectly.

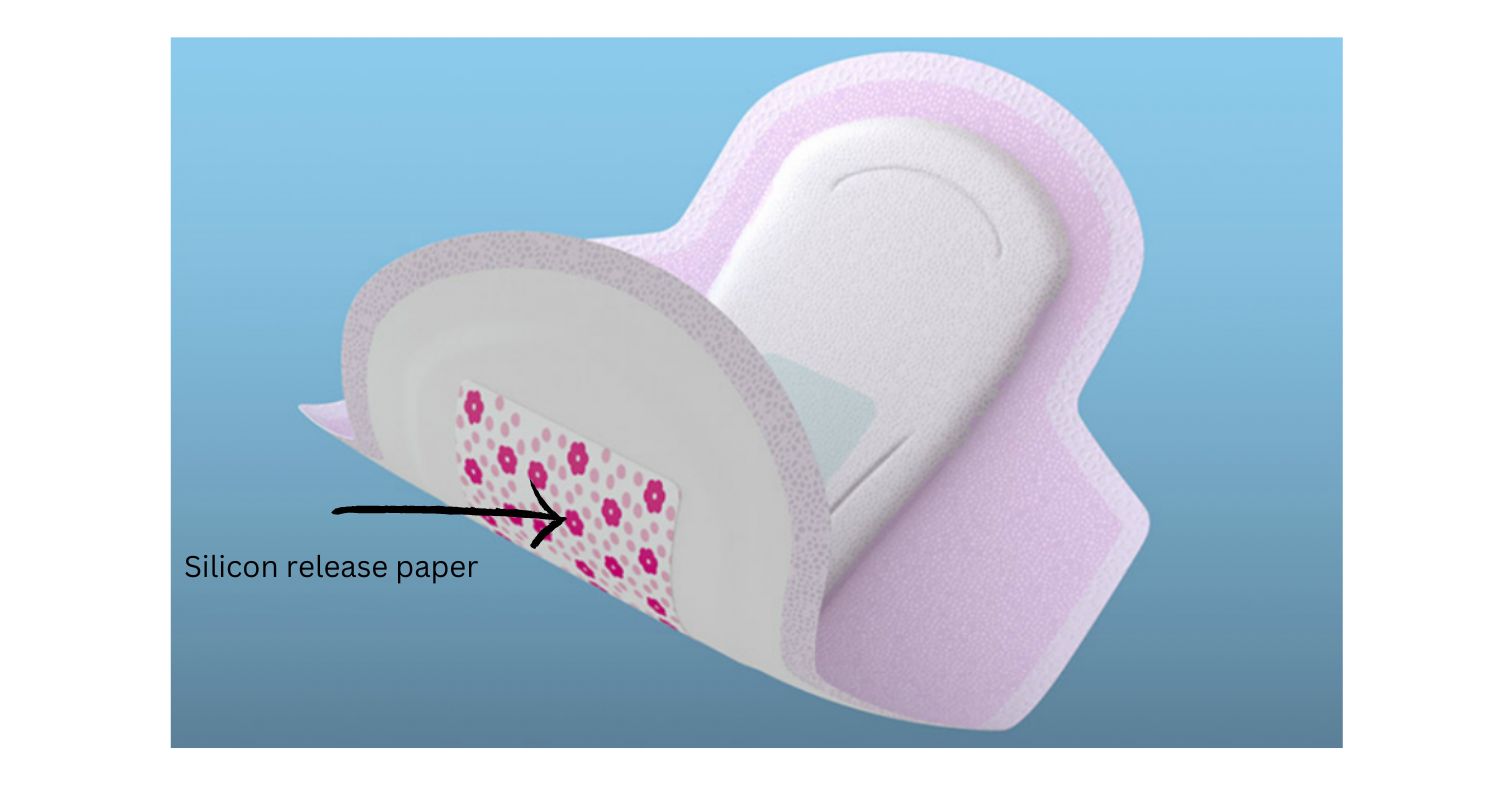

Stage 5: Gumming liner and Silicon Release paper application

This stage is essential. The sticker kind of paper available at the bottom side of the pad, which makes the pad stick on the underwear, is applied in this stage. In this stage, the complete usable pad is obtained.

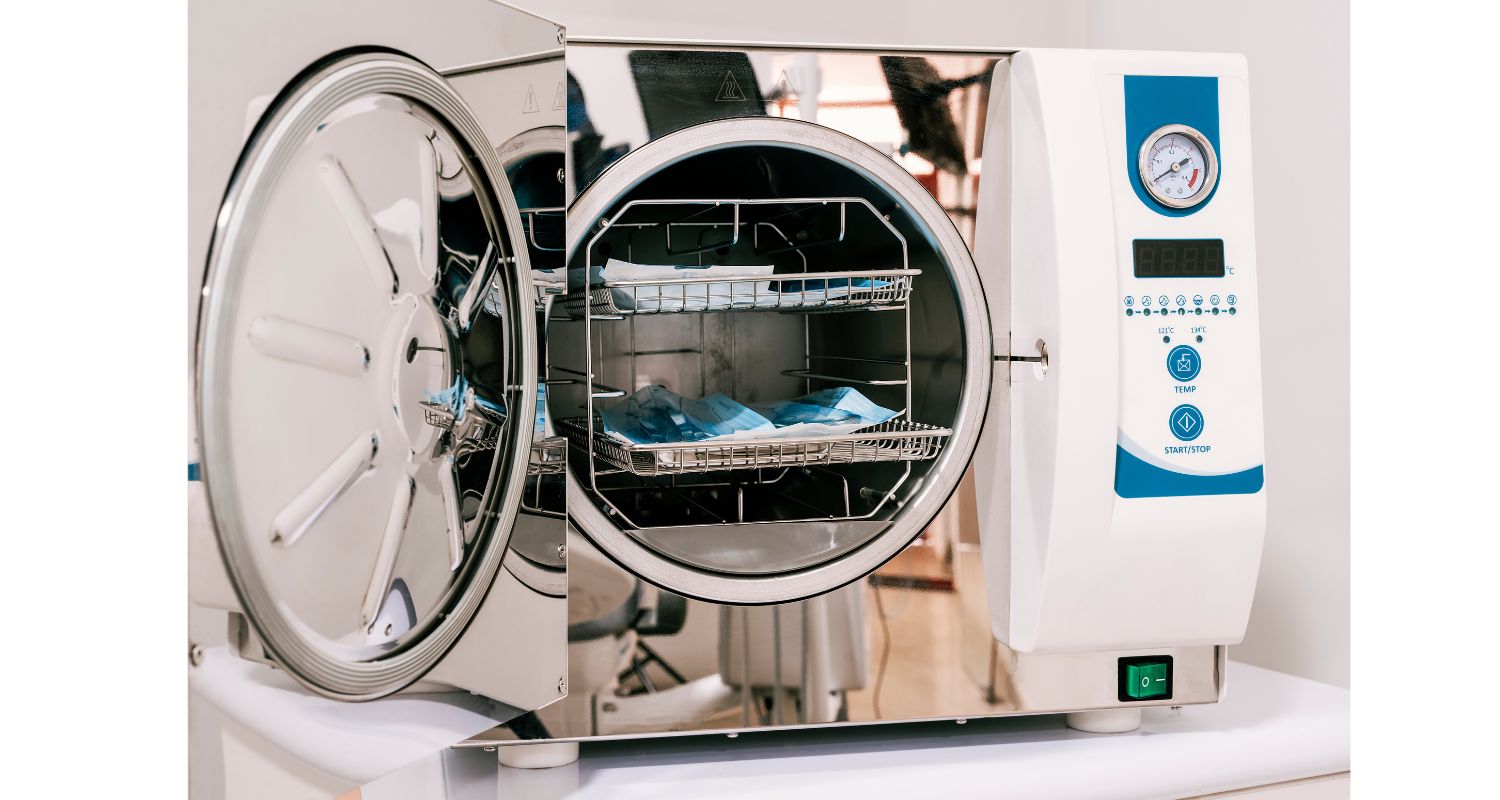

Stage 6: UV Sterilisation

This is the most critical stage after manufacturing the pad. This machine is used to reduce the probability of Microbial contamination and infections. UV sterilization is necessary to break the DNAs of germs, bacteria, and microbial contaminations in the pad and make it completely pure and hygienic for the end user.

Stage 7: Packaging

Packaging can be manual or automatic. Packaging should be unique and eco-friendly.

This is how the pads are manufactured.

This process was semi-automatic. There are automatic machines also where 70-80 pads can be manufactured in a minute. Likewise, in a day shift of 8 hours, the automatic device can manufacture around 30-35k pads.

Today’s most disposable sanitary pads are made of layers of cellulose combined with a superabsorbent polymer powder. SUPER ABSORBENT POLYMER, or SAP, has a salt-like appearance and is odourless, safe, and highly pure. Previously, it was exclusively used in powder form but is now utilized as a gel sheet. It is a hydrogel material capable of absorbing and holding hundreds of times its dry weight in water and other aqueous solutions.

There are numerous varieties of disposable menstrual pads, including:

- Regular: An absorbent pad in the median range.

- Ultra-thin: A tiny (thin) pad with less mass but the same absorption level as a Regular, Maxi, or Super pad.

- Panty liner: Created as a backup for tampons or menstrual cups, Panty liner is designed to absorb regular vaginal discharge, light menstrual flow, “spotting,” and mild urinary incontinence.

- Maxi/Super: A more excellent absorbent pad that is helpful towards the beginning of the cycle, when menstruation is frequently at its heaviest.

- Overnight: A lengthier pad with enough absorbency for overnight use, allowing extra protection while the user is lying down.

- Maternity: These are intended to be worn to absorb lochia (bleeding after childbirth) and can also absorb urine. It is often a little bit longer than a maxi/Super pad.

Conclusion

Diapers and sanitary napkins are not naturally biodegradable. As we gaze into the gloomy future of the environment in the twenty-first century, it is one of the most severe pollution problems we are attempting to remedy. Both the diapers we buy for kids and the typical sanitary napkins women use are made of a mix of plastic and cotton. Many businesses have begun to sell their products with individual plastic sheets covering every pad in the case of sanitary napkins. The outer plastic cover with the lovely graphics, the plastic sheet that covers the sticky surfaces, and the pads, which contain more plastic than cotton, are all expenses covered by the purchase of synthetic sanitary napkins.

Always choose biodegradable sanitary products. These products are manufactured with mixtures of organic materials that are simpler to breakdown rather than plastic. Additionally, they preserve the vagina’s natural bacteria and are gentler on the skin. Use reusable sanitary products if you genuinely want to show appreciation for the environment and go the extra mile. The pad can be washed and used repeatedly, as the name implies